Fleet Management

Own Your Equipment, Own Your Future

Real-world vehicle and equipment systems for independent operators

The Problem We Solve

Managing vehicles and equipment shouldn’t mean dependency on dealers, proprietary systems, or incomplete documentation. Whether you’re maintaining a single truck or an entire fleet, independent operators need practical expertise, complete documentation, and community support to truly own their equipment.

Our approach combines:

- Hands-on expertise from real-world projects

- Complete technical documentation anyone can use

- Open knowledge sharing and community support

- Field-tested solutions, not theoretical approaches

What We Actually Do

Build & Document

Real projects with complete documentation. Every repair, modification, and custom build becomes knowledge that others can use. From wiring harnesses to engine rebuilds, we document the entire process including what doesn’t work the first time.

Test & Refine

Field-tested solutions using actual equipment. Our work trucks, ATVs, tractors, and trailers serve as testing grounds for systems and procedures before we document them. Real-world validation matters more than theory.

Share Openly

Free access to documentation and procedures. We believe in the right to repair and the power of shared knowledge. Community-reviewed, continually updated, and available to anyone who needs it.

Featured Project: 24-Foot Trailer Wiring Harness

Complete documentation of a 24-foot flatbed trailer electrical system rebuild. From non-functional wiring to field-ready 7-way system with proper wire gauging, junction box installation, and systematic testing.

What’s covered:

- Complete wiring system architecture

- 7-way plug pin assignments and wire specifications

- Junction box configuration and weatherproofing

- Marker and tail light connections

- Testing methodology and troubleshooting

- Tools, parts, and budget breakdown ($290-540 total)

Our Fleet & Experience

Our fleet serves as both working equipment and field laboratory for testing systems and procedures:

Work Trucks

2014 F-350 Lariat 6.7 Powerstroke with custom aluminum work body. Active projects: front end rebuild, electrical system optimization, custom tool storage solutions. This truck serves as our mobile workshop and primary testing platform for electrical and mechanical systems.

ATVs & Utility Vehicles

Yamaha Grizzly 660 restoration and modification project. Learning ground for small engine systems, electrical troubleshooting, and rebuild procedures. Yamaha YFZ, Raptor, and Blaster series serve as platforms for understanding performance modifications and maintenance procedures.

Tractors & Implements

Kubota equipment for property management and agricultural work. Maintenance, repair, and modification experience with compact tractors and implements. Practical knowledge of hydraulic systems, PTO operations, and implement integration.

Trailers & Support Equipment

24-foot flatbed trailer with complete custom wiring harness (documented above). Custom trailer designs for specific applications. Milwaukee M12-based trailer tester for systematic electrical diagnostics.

Core Systems We Cover

Vehicle Control Systems

- Powertrain control modules

- Chassis control systems

- Body control modules (BCM)

- Diagnostic procedures

Wiring Harnesses

- Custom electrical systems

- Wire gauge specifications

- Connector selection

- Weatherproofing techniques

Engine Building

- Assembly procedures

- Measurement and tolerances

- Break-in and tuning

- Performance modifications

Chassis & Suspension

- Alignment procedures

- Suspension modifications

- Steering systems

- Brake upgrades

The Steelbak Approach

Our fleet management philosophy centers on building knowledge and capability rather than dependency:

1. Document Everything

Every project creates knowledge. We document with photos, detailed procedures, parts lists, tool requirements, and lessons learned—including what didn’t work the first time.

2. Test in Field

Real-world validation with actual equipment. Solutions must work in the field, not just on paper. We test systems under real conditions before documenting them.

3. Share Freely

Open documentation accessible to anyone. Community-reviewed content that improves with feedback. We believe knowledge shared is knowledge multiplied.

4. Build Community

Network of DIY mechanics and fleet operators supporting each other. Discord discussions, project collaboration, and shared learning accelerate everyone’s capabilities.

Learning Resources

Free Resources

- Build Documentation: Complete project write-ups with photos and procedures

- Wiring Diagrams: Detailed electrical schematics and specifications

- Discord Community: Ask questions, share projects, collaborate

- GitHub Repositories: Open source tools and documentation

Advanced Training

Our team continuously advances skills through professional training:

- HP Academy: Wiring fundamentals, engine building, alignment

- Vehicle Control Systems: Powertrain, chassis, body electronics

- Diagnostic Procedures: Systematic troubleshooting approaches

Latest Fleet Management Content

Recent projects, build documentation, and technical guides:

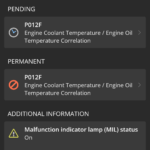

- P012F – Engine Coolant Temp / Engine Oil Temp CorrelationNo matter how much we drained, it ALWAYS read like this. How am I supposed to read this?* SOLUTION: Check while running and warm (ideally around 160-180°F Its in the… Read More »P012F – Engine Coolant Temp / Engine Oil Temp Correlation

- Warn 95060Hubs went out in Dec of 2025 when I tried to engage 4×4, which has been clunky to engage since then. They started making a “whirring” sound. I just kept… Read More »Warn 95060

- 24-Foot Flatbed Trailer: Custom Wiring Harness BuildWhen you need a 24-foot flatbed trailer for property work, non-functional lighting isn’t just an inconvenience—it’s a safety issue. This complete rebuild documents every step of creating a reliable 7-way electrical system.

- Fleet ManagementThe Problem We Solve Managing vehicles and equipment shouldn’t mean dependency on dealers, proprietary systems, or incomplete documentation. Whether you’re maintaining a single truck or an entire fleet, independent operators… Read More »Fleet Management

Join the Community

Connect with independent mechanics, fleet operators, and DIY builders:

Related Systems & Services

#WeHaveTheTools to build, maintain, and own our equipment